Additive Manufacturing

Leveraging tooling expertise and internal design capabilities, Ascent can evaluate the use of 3D printed jigs and fixtures as part of your sub-assembly and final assembly process.

Vertically integrated in-house design and fabrication allows us to recommend traditional or additively manufactured tooling solutions.

Ascent’s internal resources and relationships with industry-leading vendors gives us access to the full suite of additive technologies.

Common plastic and composite technologies

- LFAM – Industry-leading thermoplastic capability with Thermwood 10’x40’ LSAM

- Stereolithography (SLA) – ideal for rapid plastic prototyping and small jigs, fixtures, and shop aids

- Laser Sintering (SLS) – high-resolution production parts using Nylon

- Fused Filament Fabrication (FFF/FDM) – flexible prototyping with variety of material & filler

Common metallic technologies

- Direct Metal Laser Sintering (DMLS) – powder-based process for complex geometries and high-value materials

- Direct Energy Deposition (DED) – wire-based process for rapid deposition

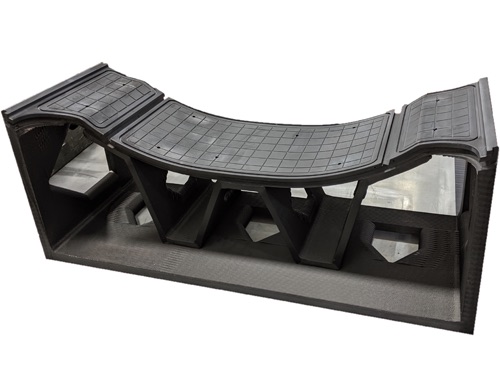

Large Format Additive Manufacturing (LFAM) Capabilities

- Thermwood LSAM machine is installed and is fully operational in Santa Ana, co-located with Ascent’s composite shop

- 10’x40’ build area capable of depositing a wide variety of thermoplastic materials, including ABS, PC, Nylon, and PEEK

- Vacuum mill fixtures, holding fixtures, handling tools, check fixtures, master molds, layup molds, prototypes

What does your manufacturing excellence look like?

Contact us and we’ll answer that together.